Next-Gen Refrigeration

New regulations. New refrigerants. Same RDT support.

A2L Transition: Where Things Stand Now

(Updated 12/05/2025)

The industry is still operating under the January 1, 2026, A2L Transition implementation date while the EPA reviews public comments on its proposed rule. Until a final rule is published, the AIM Act Technology Requirements remain fully in effect.

Key milestones so far:

- Proposed rule published October 3, 2025

- Public hearing held October 20, 2025

- Comment period closed November 21, 2025

What could shift:

Enforcement timing, Global Warming Potential (GWP) limits, or application categories, depending on the final rule.

What won’t change:

The long-term move to lower-GWP refrigerants. A2L systems will continue to shape future refrigeration design.

RDT will keep this A2L Resource Hub updated as new details emerge so operators and partners have a clear and informed path forward.

.

What is the new EPA Proposed Rule on A2L?

Explore our continually updated blog for the latest regulatory insights.

How Are A2L Systems Different from Traditional Refrigeration Systems?

A2L systems are engineered with additional safety, ventilation, and leak detection measures to account for the mild flammability of the refrigerant. These design differences ensure compliance with updated safety standards like UL 60335-2-89 and ASHRAE 15.

Key Differences in A2L Systems

1. Leak Detection Systems

Required in most applications using A2Ls

Monitors for refrigerant leaks in enclosed spaces

Automatically triggers alarms or system shutdown if thresholds are exceeded

2. Ventilation or Airflow Management

May require mechanical ventilation in equipment rooms or confined spaces

Prevents refrigerant concentrations from reaching flammable levels

3. Charge Size Limits

Subject to strict maximum charge amounts based on room size, application, and presence of leak detection

System design must account for these limits to stay compliant

4. Spark-Free Electrical Components

Components in areas where refrigerant may accumulate must be ignition-protected or spark-free

5. Safety Control Logic

Built-in logic shuts down compressors and activates ventilation systems automatically in the event of a leak

What Are A2L Refrigerants? Why Are They Important?

A2L refrigerants are low-GWP (Global Warming Potential), mildly flammable alternatives to older refrigerants like R-404A. They are essential for meeting EPA and AIM Act regulations taking effect January 1, 2026.

💡 Want to understand how this regulation impacts your operation?

[Download our full A2L Transition Guide]

When Is the EPA’s A2L Refrigerant Deadline?

Deadline: January 1, 2026

All new refrigeration systems must use compliant, low-GWP refrigerants like A2Ls by this date. Compliance is based on the installation date, not the purchase date.

📅 Need help planning your timeline?

[Grab the checklist in our free guide]

Can I Retrofit My Existing Refrigeration Systems to Use A2Ls?

In most cases, no. Retrofitting is not allowed due to pressure and flammability differences. A full system replacement is usually required.

🛠 Not sure whether to replace or upgrade?

[Get expert advice in our A2L Transition Guide]

Are There Safety Considerations for A2L Refrigerants?

A2L systems require:

Proper ventilation and airflow controls

Certified leak detection systems

Tools and equipment rated for use with flammable refrigerants

🧯 Explore our safety checklist in the full guide

[See the checklist]

Will Switching to A2L Refrigerants Save Energy or Cost More?

While upfront costs may be higher, A2L systems often deliver 5–10% energy savings compared to legacy HFC systems—providing a long-term return on investment.

⚡ Explore the energy efficiency comparison

[Download the guide]

How Can I Prepare for Supply Chain Delays Ahead of the 2026 Deadline?

Start sourcing compliant equipment early

Build relationships with trusted suppliers

Align early with inspectors and insurance providers

📦 Our guide walks you through every prep step

[Get the planning guide]

What codes or standards apply?

Are there any installation differences compared to A1 refrigerants?

Yes. Most A2L installations will include:

Refrigerant shut-off valves in the suction and liquid lines, installed outside walk-ins

Control via evaporator controller with leak detection sensors

Possible requirements for fire-rated shafts or ventilation systems

Always refer to local building, mechanical, and fire codes along with ASHRAE 15.

Do servicers need special tools to work on A2L equipment?

Yes. Tools must be certified for flammable refrigerants:

Recovery machines, vacuum pumps, hoses, and gauges must be A2L-rated

Spark-proof tools are often required

Open flames or ignition sources must be avoided during service

Will A2L Refrigerants Require New Components?

Yes. A2L-compliant systems require:

Specially designed compressors, condensers, and expansion valves

Electrical components (e.g., contactors, pressure switches, relays, controllers) rated for A2L compatibility

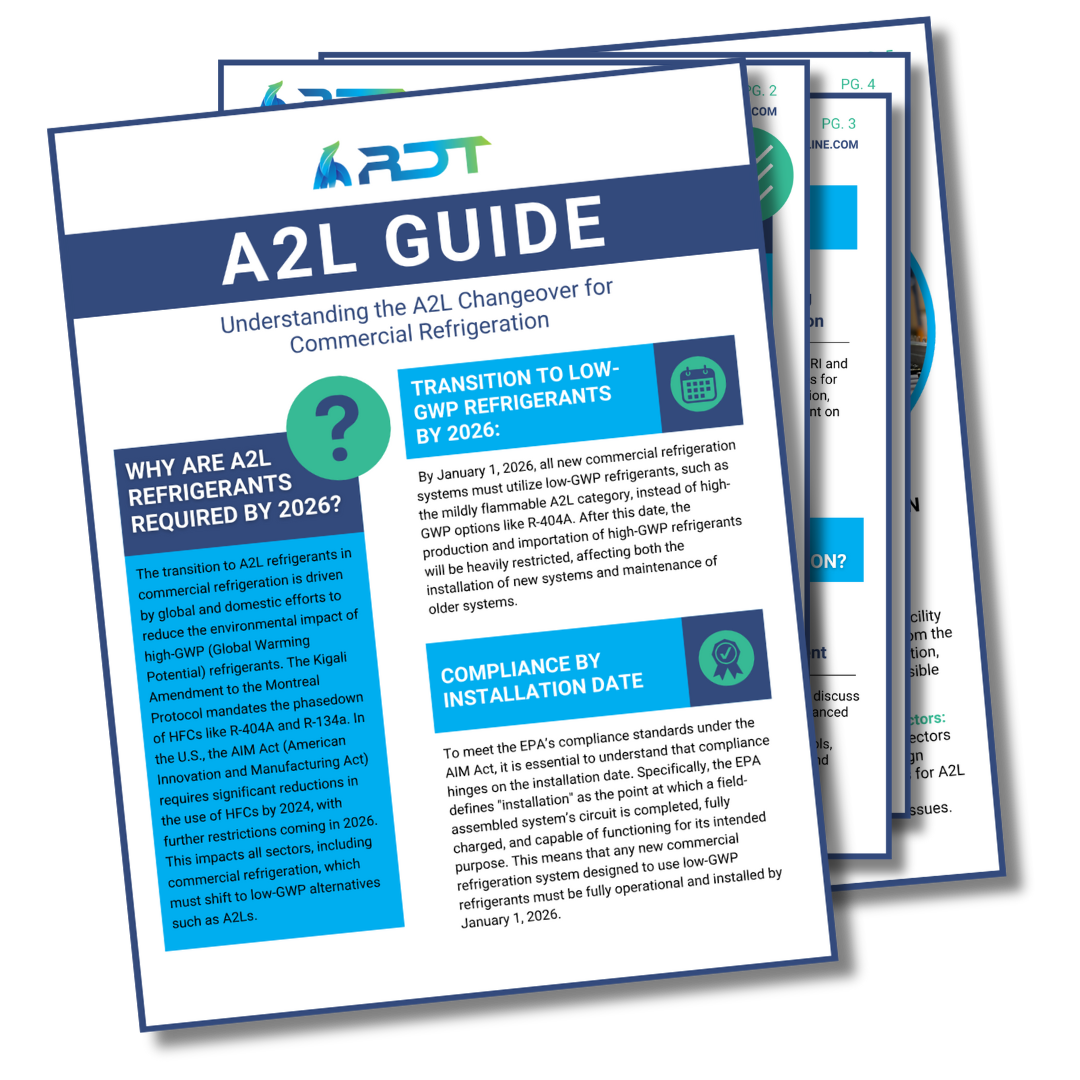

A2L Refrigerant Transition Guide

Don't get left behind in the A2L refrigerant transition. Our comprehensive guide provides essential insights and actionable steps to ensure your compliance and success forthe January 1, 2026 deadline.

WHAT'S IN THE GUIDE?

Future-Proof Plan

Stay ahead of industry trends and position your business for long-term success in the evolving refrigeration landscape.

Regulation Timeline

Clear timeline of EPA regulations and deadlines for A2L adoption.

Bonus: Checklist

Unlock the power of preparedness with our exclusive checklist – your roadmap to A2L compliance success!