Knowing how refrigeration works is crucial to finding the right solutions for your foodservice operation, and fortunately, the basics are easy to understand and quite interesting to learn.

Understanding the Refrigeration Cycle

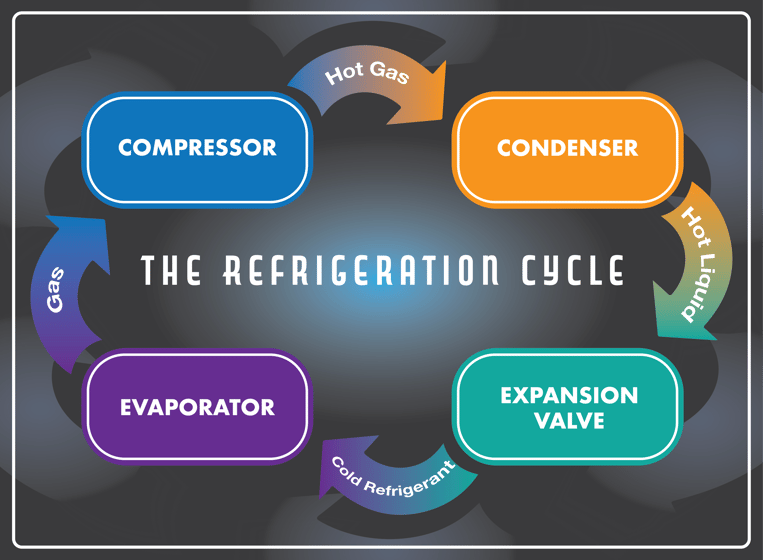

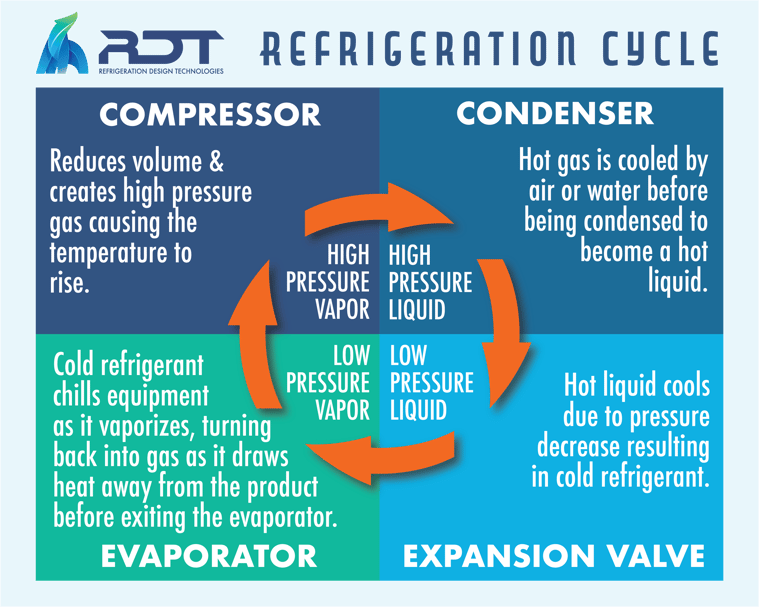

In simple terms, a refrigeration cycle's mission is heat absorption and heat rejection. As we often tell our customers, you can't make cold, you can just remove heat. The refrigeration cycle is a means of routing heat away from the area you want to cool. This is accomplished by manipulating the pressure of the working refrigerant.

The refrigerant starts its journey in the compressor, where it gets pressurized into a hot gas. Yes, it actually starts out very hot!

Next, the refrigerant enters the condenser. The condenser cools the refrigerant by transforming it into its liquid state, though it’s still hot at this stage. It’s important to protect the condenser because it’s highly susceptible to corrosion. Fortunately, RDT treats its condensers with a protective coating.

After the refrigerant has been liquified, the thermostatic expansion valve reduces the refrigerant’s pressure and cools it even more. The sudden drop in pressure and temperature produces a cooling effect.

Finally, the evaporator absorbs heat into the refrigerant from the items in the walk-in. As the refrigerant heats up, the evaporator vaporizes it and pushes it back into the compressor, starting the cycle over again.

How RDT Sizes Refrigeration Systems

There are a lot of factors that determine the size needed for a refrigeration system. Of course we need the dimensions of the walk-in, the external climate, elevation, and proximity to the ocean are just some of the considerations.

For locations within 20 miles of the ocean, the salty air can damage the aluminum fins of the condensers. RDT will evaluate each location and coat the condensers with a proper protective coating, if necessary.

Whether it’s an extremely hot or cold location, RDT project managers will research annual temperatures and size each system based on the external conditions. In hot environments, we will oversize the condensers. In extremely cold environments, it may be necessary to add heat inside the cabinet as the receivers need to be warm enough for the refrigerant to stay liquified within the condensers.

Evaporator coils can run differently depending on the altitude of a location. So, elevation also factors into the size needed for a refrigeration system. RDT can advise on the best options for an exact area.

Solutions From RDT

RDT offers 4 unique refrigeration solutions to create ideal environments for any space:

Eco-Cool Series

The Eco-Cool Series was developed to be an environmentally friendly option with precise temperature control and flexible load matching to replace numerous compressors with a single digital compressor. Of course, with built-in redundancy! Fewer compressors result in a smaller footprint, significant refrigerant reduction, improved energy savings, and a reduction in installation costs.

Eco-Smart Series

The Eco-Smart Series is an evaporator controller that eliminates unnecessary defrosts cycles and defrosts only when needed, and can also be monitored and managed remotely. RDT can also upgrade existing equipment with the Eco-Smart Series.

RDMC Series

The outdoor-air cooled RDMC Series is perfect for multiple-fixture complexes. This series features a multi-circuited condenser, stainless steel housing, and includes up to 15 compressors. It also allows circuit integration for ice machines.

ZS Series

Also outdoor-air cooled, the ZS Series is great for cooler/freezer combo boxes. It features dedicated oversized condensers and can hold up to 10 compressors.