1 min read

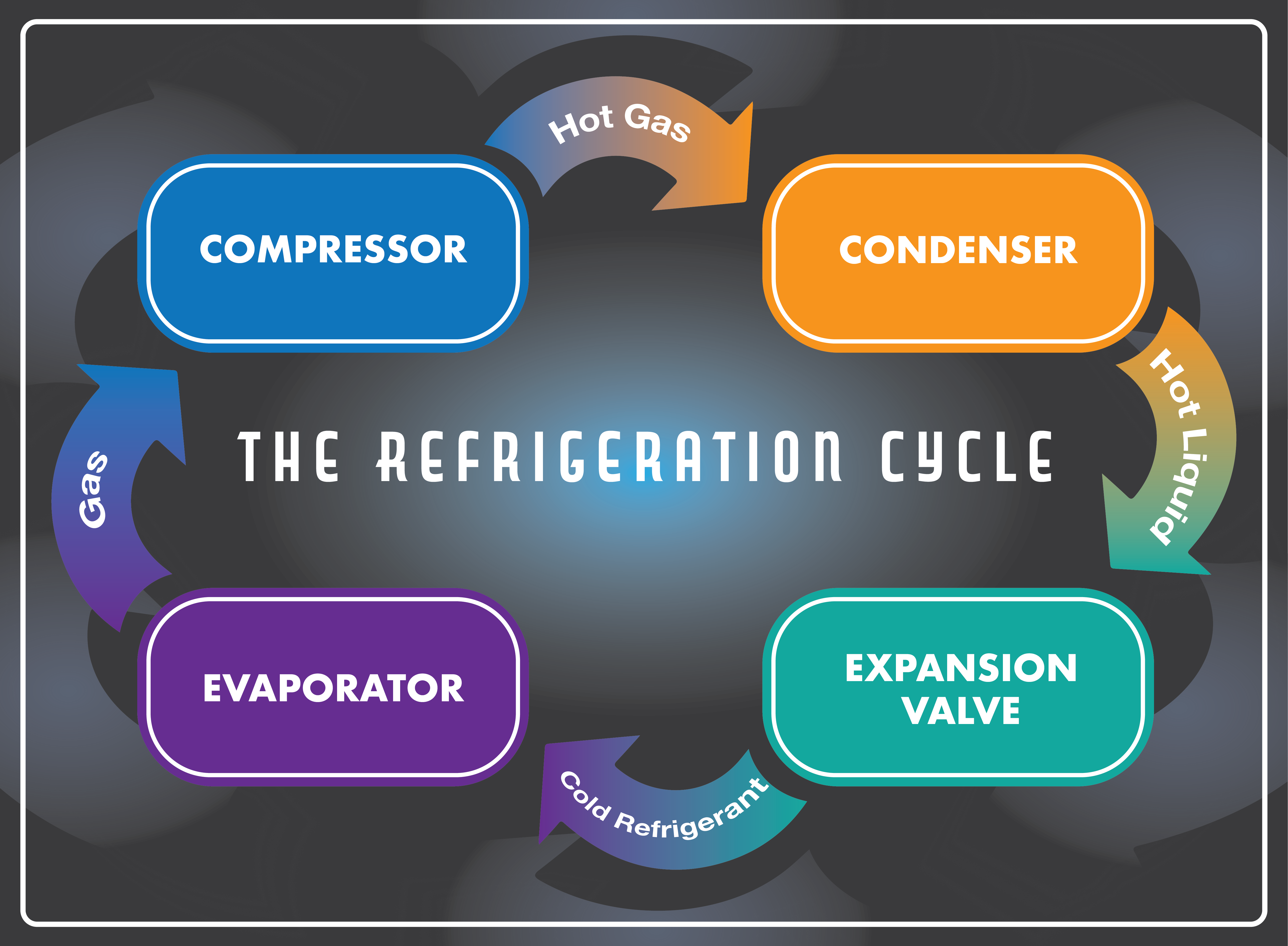

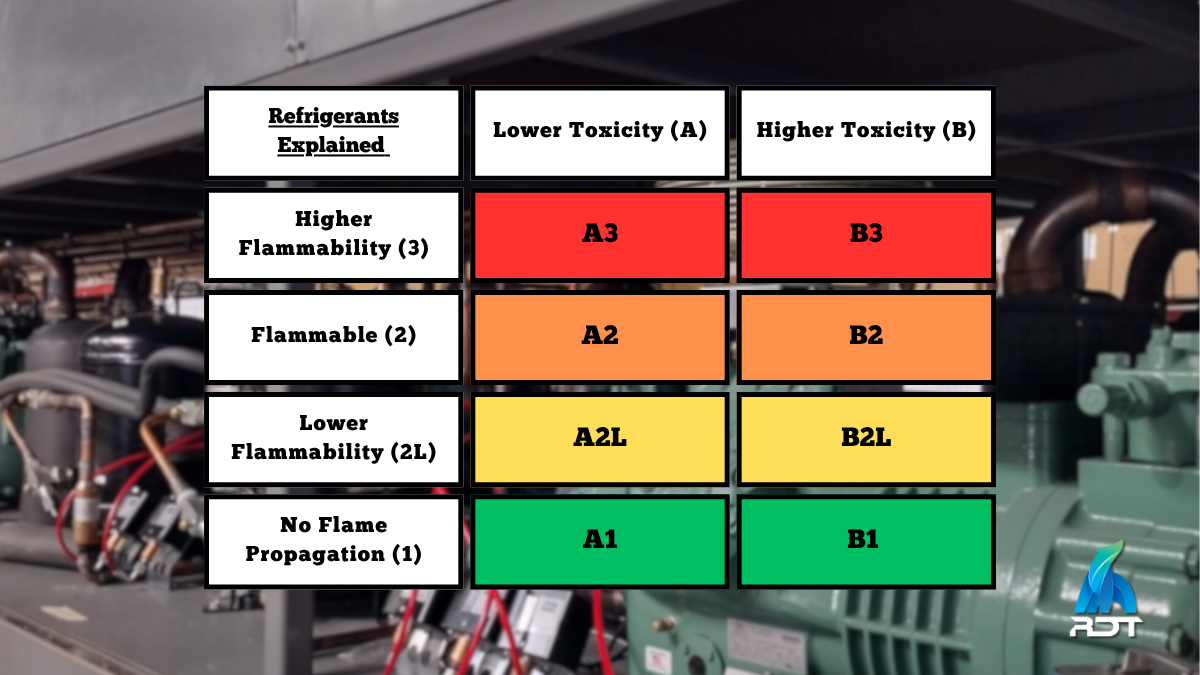

The world around us continues to launch new technologies that transform and enhance our day-to-day lives, and developments in refrigeration technologies are no different. Innovations have resulted in the implementation of advanced compresso...

Read More