Is your evaporator coil plug and play? Does it require the refrigeration installer to add components on site? Does it involve the electrician running interconnective power and control wiring from the evaporator to the condensing unit? Why does it really matter? This is a subject we've heard people talking a lot about, so we wanted to dig into the details.

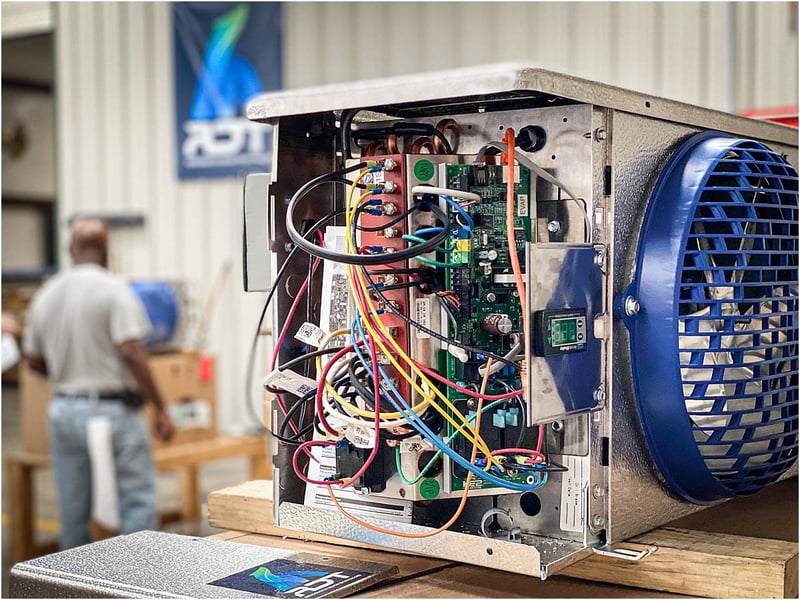

The reality is that all evaporator coils require the addition of an expansion valve, solenoid, and a thermostat (or temperature sensor) to be fully operational. Traditionally, these additions were installed in the field and this process was wrought with added labor cost and, sometimes, inferior results. RDT was the first in the industry to factory-install these components in our commercial refrigeration units, along with a convenient on/off switch for trouble-free pump down.

In addition to labor rates for adding supplemental components, interconnective wiring costs of the electrical contractor can start to add up quickly when connecting power and control wiring to evaporator coils. Consider five to seven wires running 100+ feet for each evaporator. RDT’s solution is to factory-install all sensors and controls within the evaporator cabinet, which eliminates all interconnective wiring between the evaporator and condensing unit. The electrician simply needs to bring house power to the evaporator.

Retrofitting your evaporator coils can create more advantages than just ease at install.

Plug and play evaporator coils are Department of Energy Compliant and provide great potential for energy savings. When you retrofit your evaporator coils, it can lead to lower energy bills. Let's take a deeper look at why.

Consider evaporator coils and defrost cycles. Traditionally, evaporator coils use timers to kickstart the defrost cycle in a freezer coil. More energy-efficient options like RDT's Eco-Smart provide on-demand capabilities, which means your defrost cycle runs only when it's needed.

%20You%20Should%20Coat%20Your%20Commercial%20Refrigeration%20Condensers.jpg?width=500&name=Why%20(and%20When)%20You%20Should%20Coat%20Your%20Commercial%20Refrigeration%20Condensers.jpg)